Woven Mesh

Woven mesh is made by weaving individual wires over and under each other in a crisscross pattern—much like traditional fabric weaving. This creates a flexible yet strong mesh structure with precise and uniform openings. It is commonly used for filtration, sieving, protection, and reinforcement across many industries.

Woven mesh is typically made from stainless steel, brass, copper, aluminum, or galvanized steel, and is available in various weave types and mesh counts depending on the application.

Key Features & Benefits

- Precision and Uniformity: Consistent and accurate aperture sizes ensure reliable filtration and screening performance.

- Flexibility: The woven structure allows for shaping and forming without cracking.

- Durability: When made from metals like stainless steel, woven mesh offers excellent resistance to wear, heat, and corrosion.

- Versatility: Suitable for both fine and coarse filtration, structural uses, and decorative applications.

Common Applications

- Filtration: In water treatment, chemical processing, oil refining, and food & beverage industries.

- Screening and Sieving: Used in mining, agriculture, and pharmaceuticals.

- Architectural and Decorative: For facades, ceilings, and partitions.

- Security and Protection: Window screens, machine guards, and fencing.

- Heat and Spark Protection: In kilns, grills, and heat shields.

Material Options

- Stainless Steel: High corrosion resistance, ideal for industrial and food-grade environments.

- Brass & Copper: For electrical conductivity and decorative uses.

- Galvanized Steel: Cost-effective with rust protection.

- Aluminum: Lightweight and corrosion-resistant.

Specifications

- Mesh Count: Number of openings per linear inch (ranges from very fine to coarse).

- Wire Diameter: Affects strength and flow rate.

- Aperture Size: Size of the openings between wires.

- Roll and Sheet Sizes: Available in custom dimensions to suit specific needs.

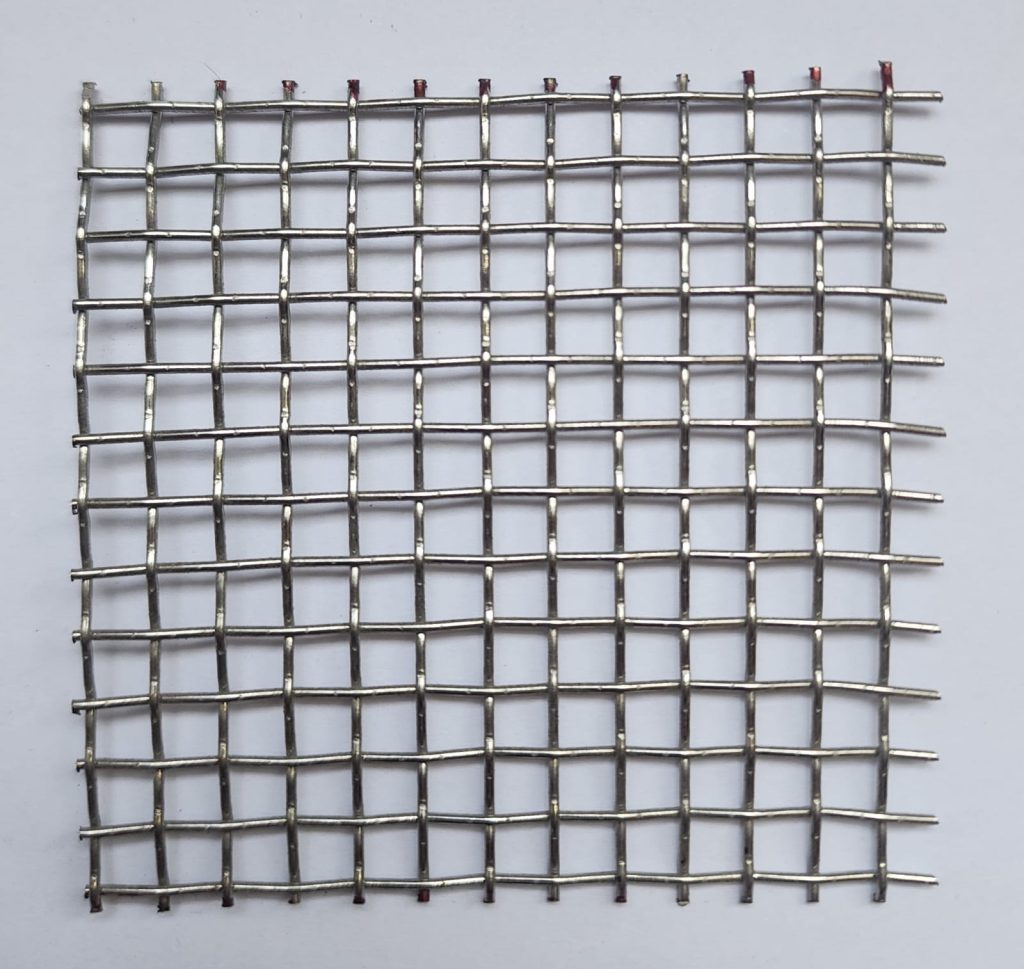

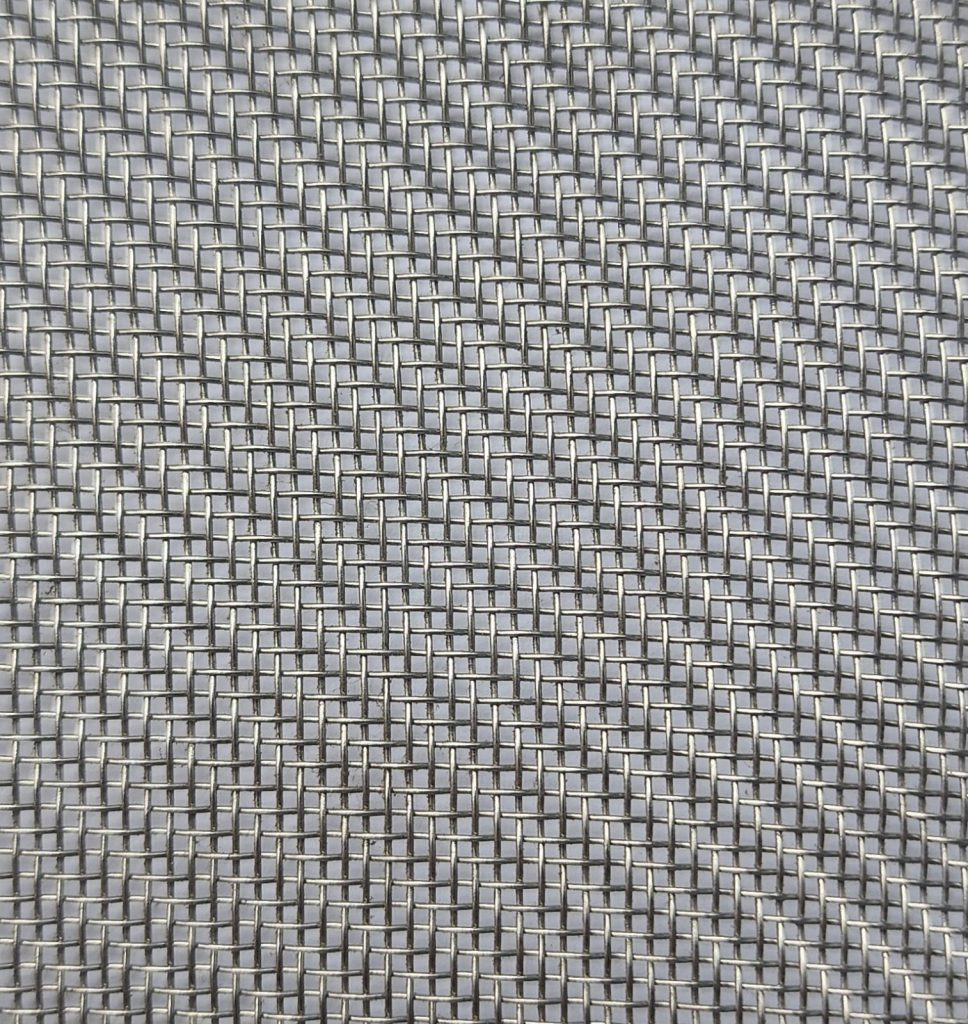

Woven - Plain Mesh

- The most common type: each wire crosses over and under the next in an alternating pattern.

- Offers good stability and is ideal for light to medium-duty applications.

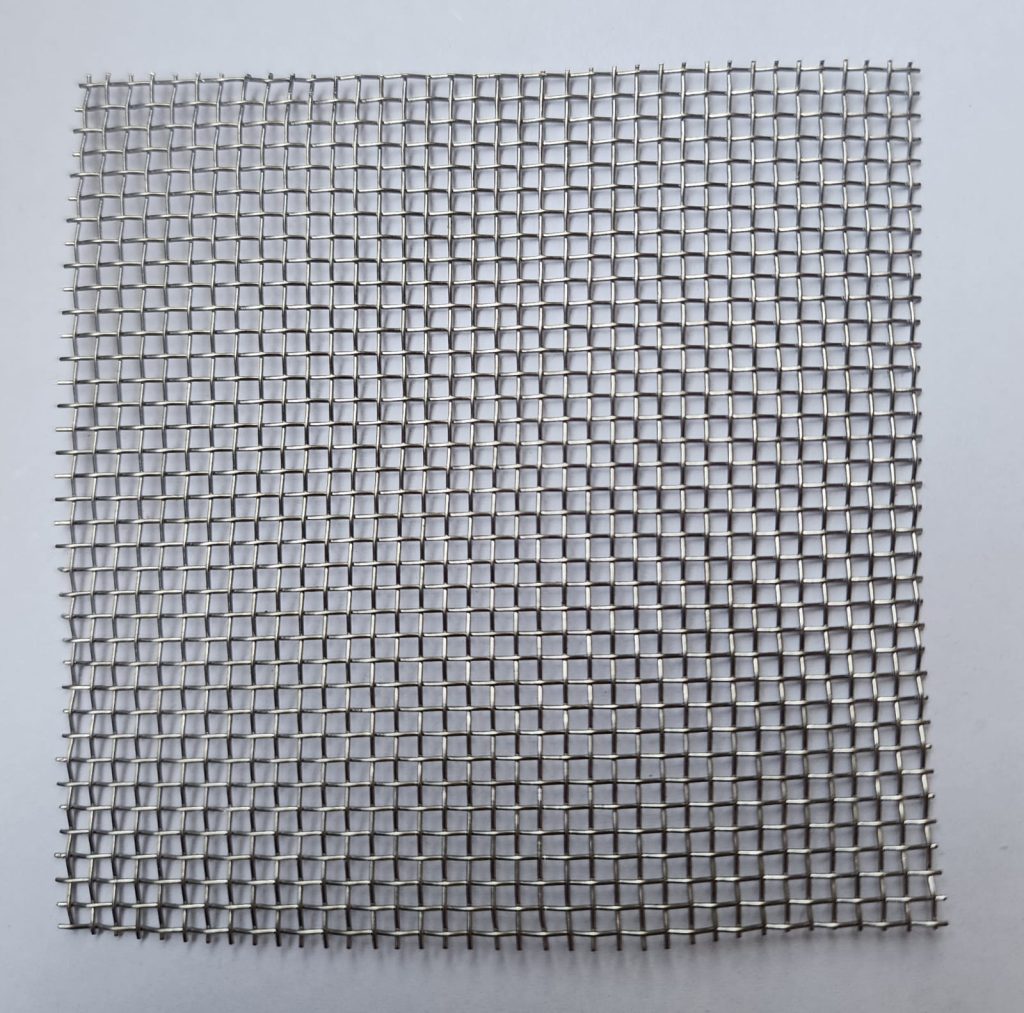

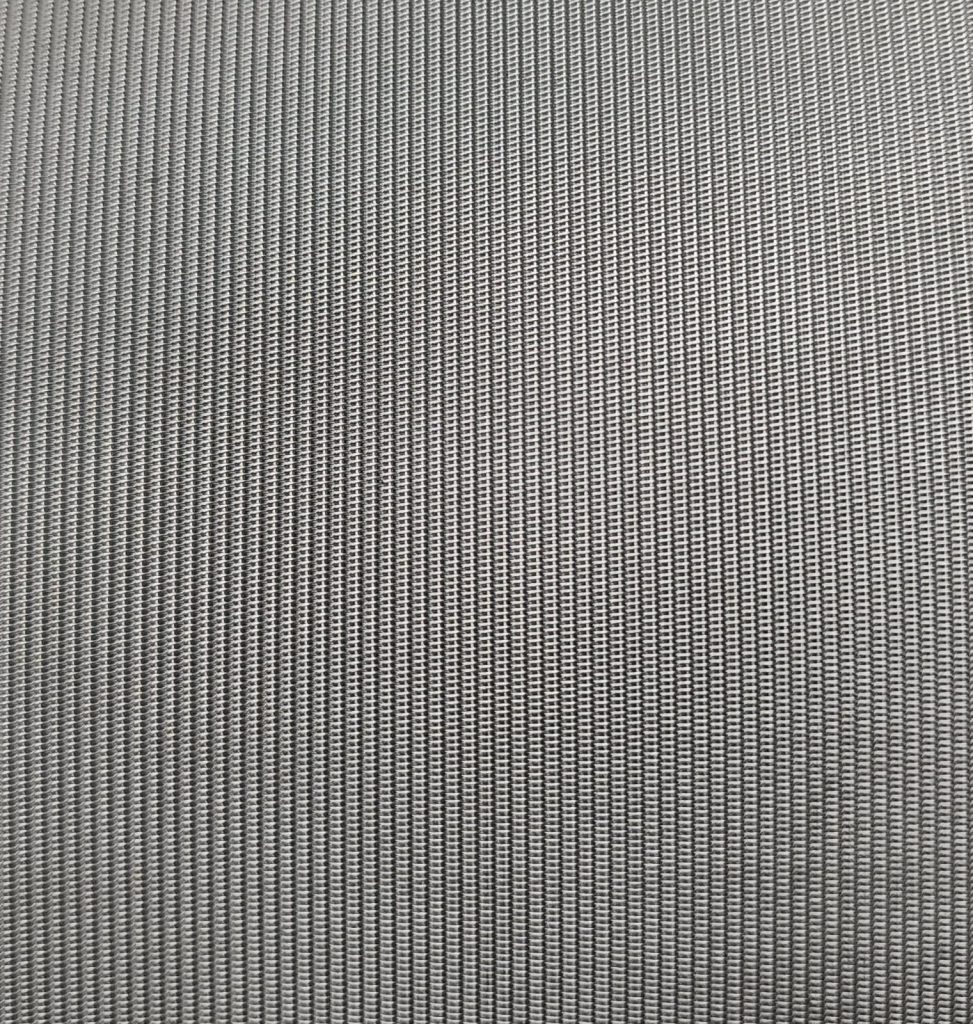

Woven - Twill Mesh

- Each wire passes over two and under two, forming a diagonal pattern.

- Provides higher strength and finer filtration than plain weave.

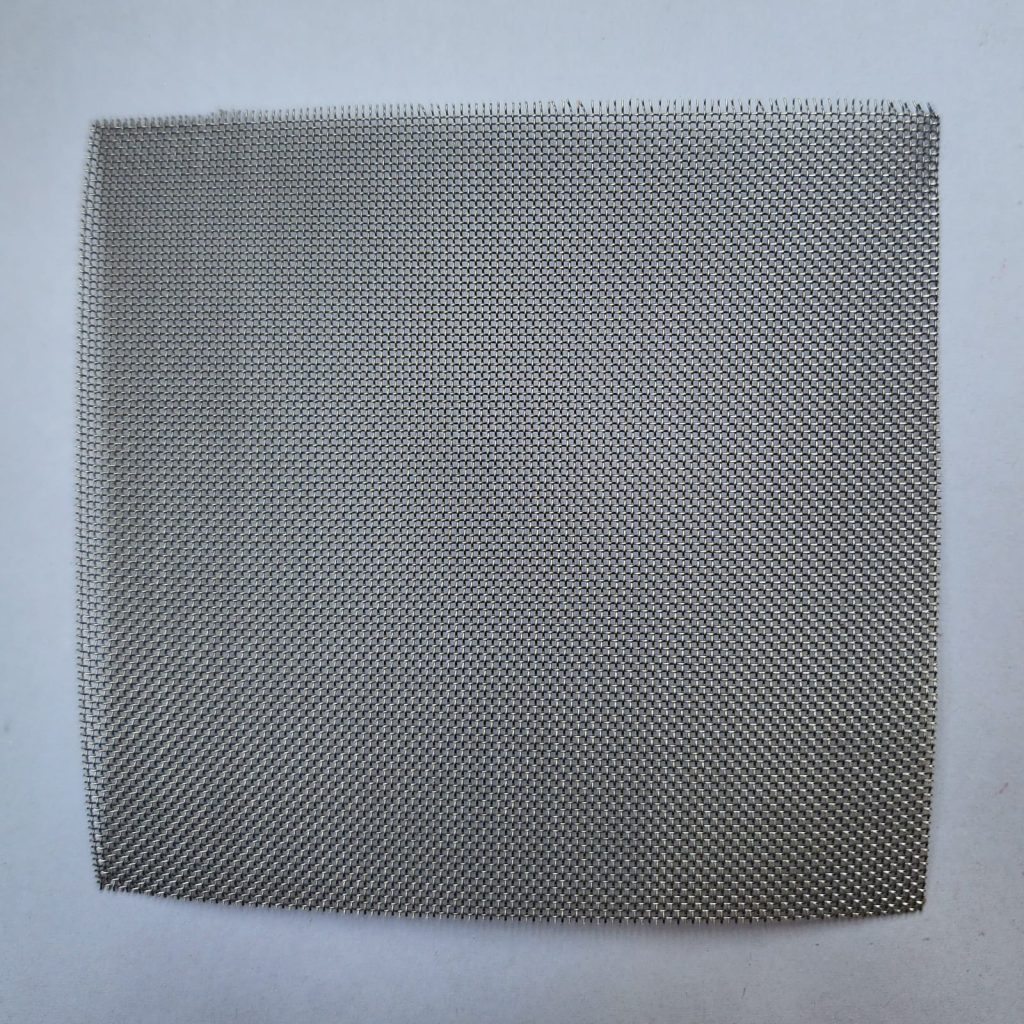

Woven - Plain Dutch Mesh

- Uses thicker warp wires and finer weft wires, creating a tighter mesh.

- Excellent for fine filtration and liquid/gas separation.

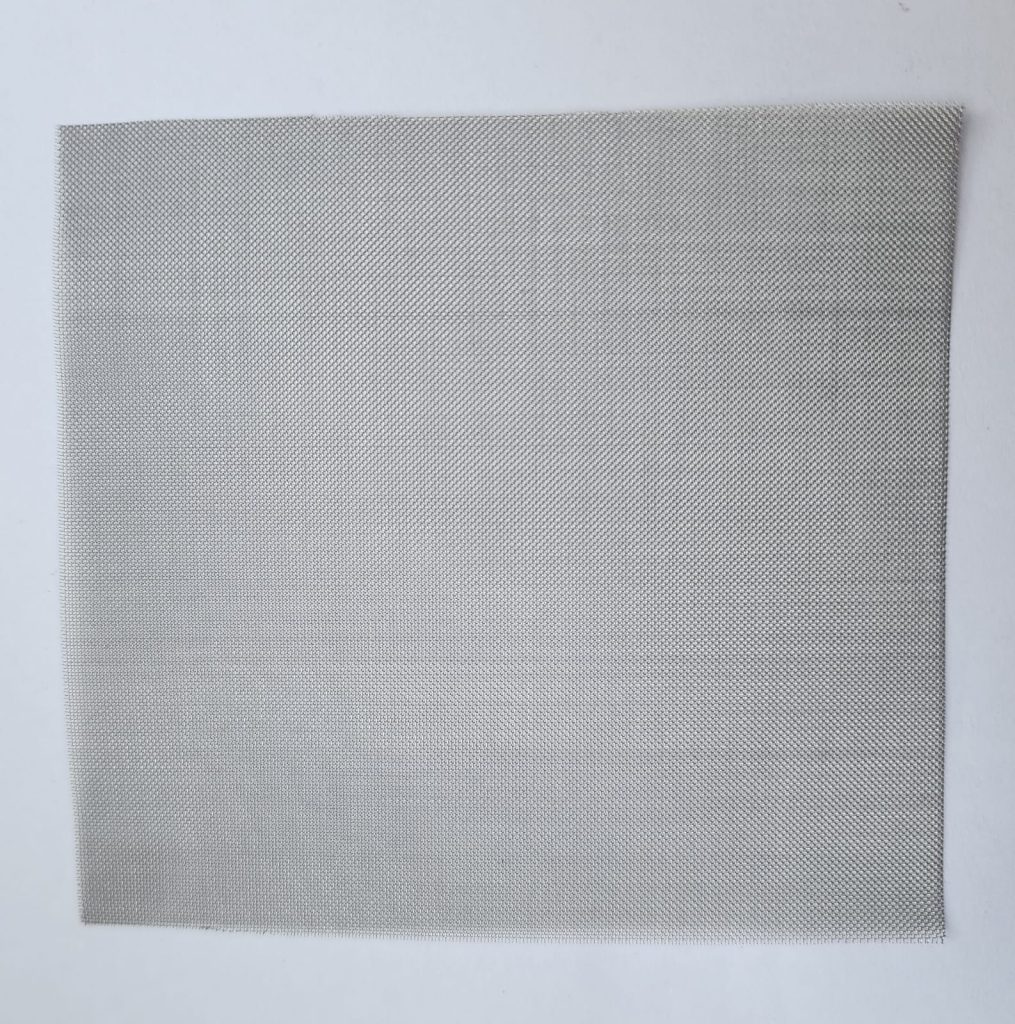

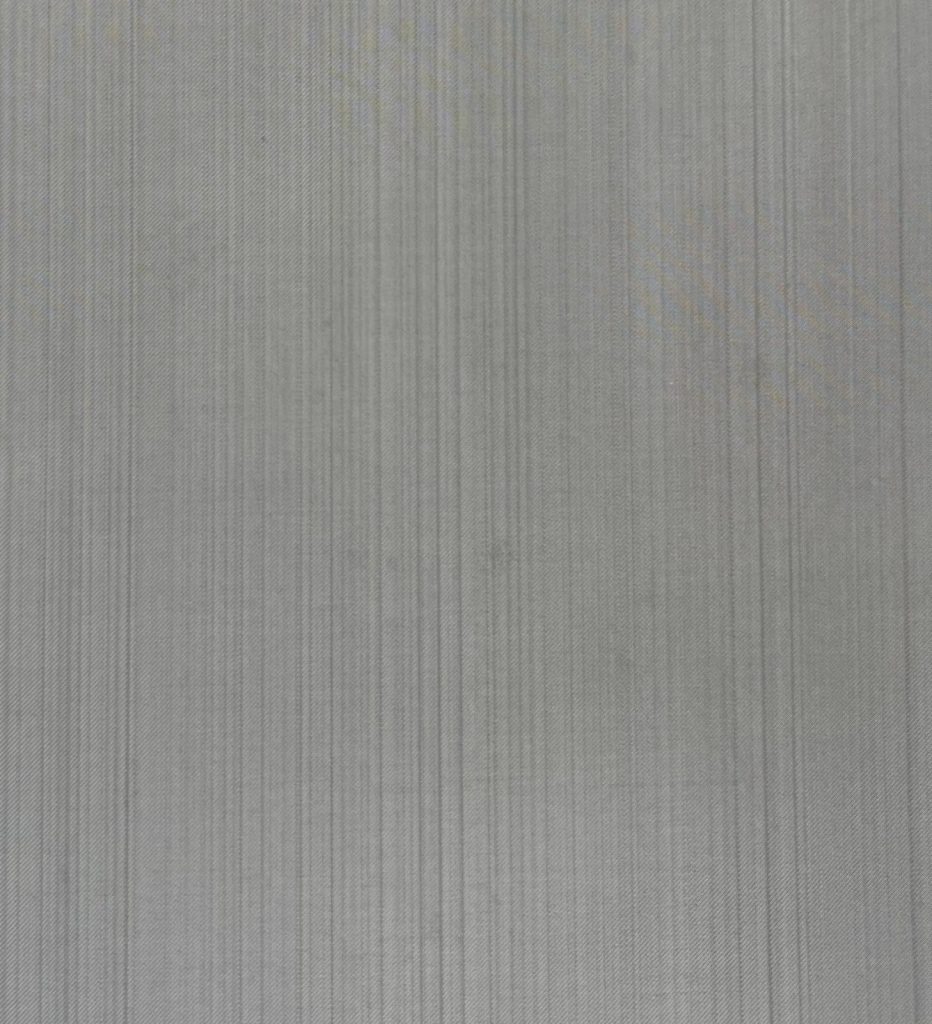

Woven - Twilled Dutch Mesh

- Similar to Plain Dutch weave, except that the weave is twilled.

- Used for critical filtration applications often under high pressure.

Woven - Reverse Dutch Mesh

- Opposite configuration of standard Dutch weave, used for high-flow applications with fine filtration.