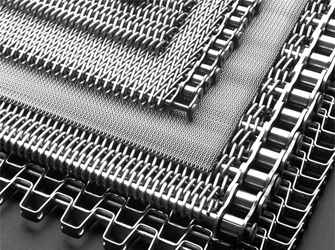

Conveyor Belt Mesh

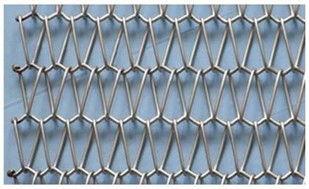

Conveyor belt mesh, also known as wire mesh belting, is a type of metal conveyor system made from interlinked wire strands. These belts are designed to handle high temperatures, heavy loads, and continuous operation in demanding environments. With excellent airflow and drainage properties, conveyor mesh belts are ideal for processing, baking, drying, and transporting materials across a wide range of industries.

Available in various wire patterns, materials, and belt configurations, conveyor mesh offers flexible, durable, and hygienic solutions for both light and heavy-duty applications.

Key Features & Benefits

- Durability: Engineered for high tensile strength and longevity under continuous operation.

- Temperature Resistance: Suitable for high-heat processes such as baking, heat treating, or sintering.

- Open Structure: Allows airflow, drainage, or heat transfer—essential for drying, washing, or freezing.

- Low Maintenance: Resistant to clogging, corrosion, and abrasion, reducing downtime and repair costs.

Applications

- Food Processing: Baking, cooling, freezing, drying, and conveyorized cooking.

- Industrial Manufacturing: Heat treatment, annealing, powder coating, and parts washing.

- Packaging Lines: Conveyor systems in bottling, canning, and product assembly.

- Textile & Printing: Fabric handling and drying systems.

- Electronics: Sintering and soldering operations.

Material & Finish Options

- Stainless Steel (304, 316): Corrosion-resistant and food-safe, suitable for sanitary or high-moisture environments.

- Galvanized Steel: Economical and rust-resistant; good for moderate-duty industrial applications.

- Carbon Steel: High strength for heavy loads or non-corrosive environments.

- High-Temperature Alloys (Inconel, etc.): Ideal for extreme heat or chemically aggressive conditions.

Common Specifications

- Belt Types:

- Balanced weave (M1)

- Compound balanced weave (M2)

- Flat flex belt (MHR)

- Flat wire belt (MFR)

- Rod-reinforced belt

- Chain-driven mesh belt

- Wire Diameters: From 0.9 mm to 5 mm

- Belt Widths: Standard and custom widths up to 2000 mm

- Edge Finishes: Welded, chain link, or clinched edges for enhanced durability

- Temperature Range: Up to 1150°C (depending on material)

Customization Options

- Tailored belt designs for specific equipment

- Reinforced edges or side guards

- Variable pitch and wire density

- Food-grade or high-temp coatings

- Installation-ready packaging or rolls

Industries We Serve

- Food & Beverage

- Pharmaceutical

- Automotive

- Glass & Ceramics

- Metal Processing

- Electronics Manufacturing

- Textile Industry