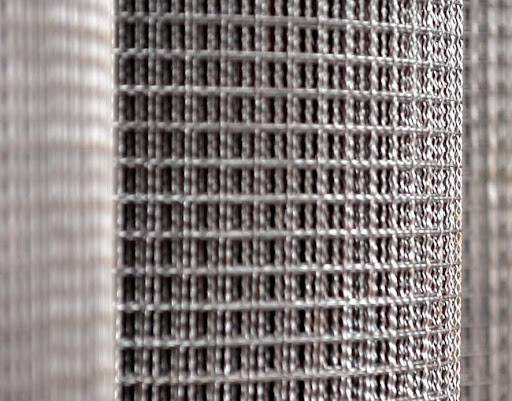

Crimped Mesh

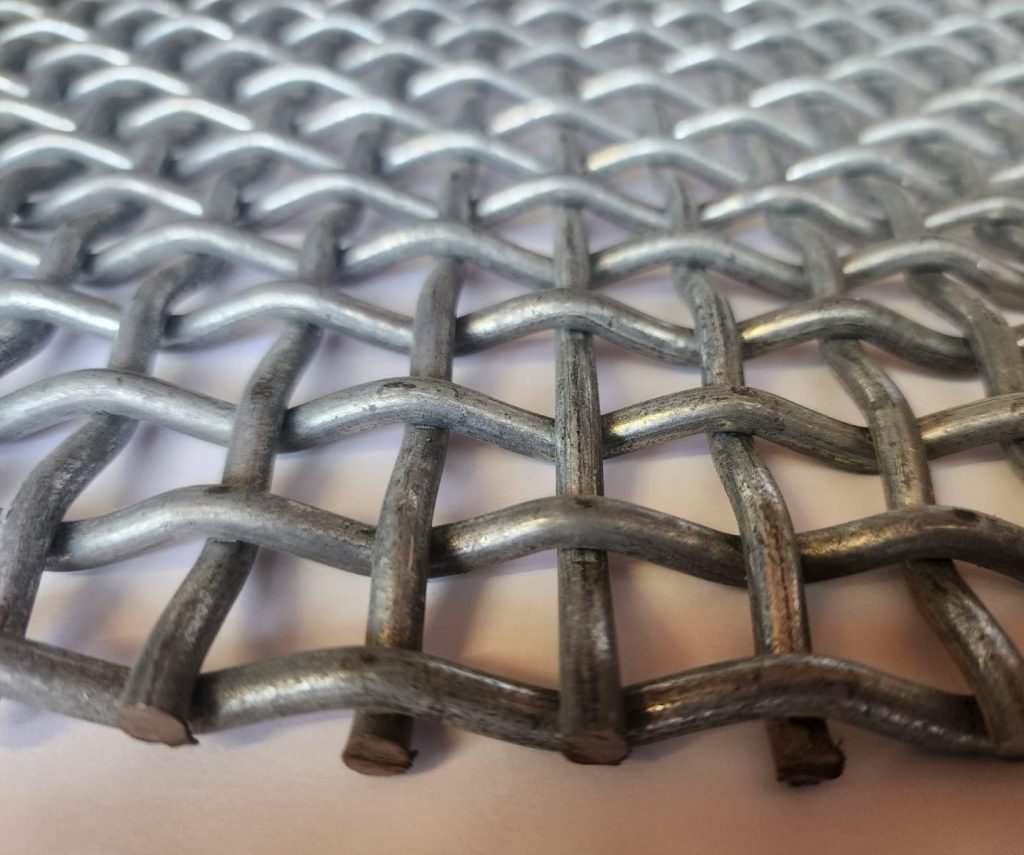

Crimped wire mesh is made by weaving or interlocking wires that have been bent or crimped into a specific pattern before weaving. This crimping process adds extra strength and rigidity to the mesh by locking the wires firmly in place. The mesh typically features square or rectangular openings, with the crimped wires ensuring consistent spacing and enhanced structural stability.

Crimped wire mesh is commonly made from materials such as stainless steel, galvanized steel, or mild steel, and is available in various wire diameters and mesh sizes to suit different applications.

Key Features & Benefits

- Increased Strength: Crimped wires hold tightly together, providing enhanced rigidity and resistance to deformation under stress.

- Durability: The crimped pattern helps distribute loads evenly, making the mesh suitable for heavy-duty and demanding environments.

- Consistent Openings: Crimping ensures uniform wire spacing and precise mesh dimensions.

Common Applications

- Filtration and Screening: Used in mining, quarrying, and industrial filtration to separate materials by size.

- Security Fencing: Provides a robust barrier with limited flexibility.

- Material Handling: Conveyor belts, sieves, and sorting equipment.

- Architectural and Decorative Uses: Facades, partitions, and cladding.

- Agriculture: Animal cages, pens, and protection barriers.

Material Options

- Stainless Steel for corrosion resistance and longevity.

- Galvanized Steel for cost-effective rust protection.

- Mild Steel for interior or less corrosive environments.

Specifications

- Mesh sizes range widely depending on application.

- Wire diameters typically vary from fine to heavy gauge.

- Available in panels or rolls, customizable to specific sizes and finishes.

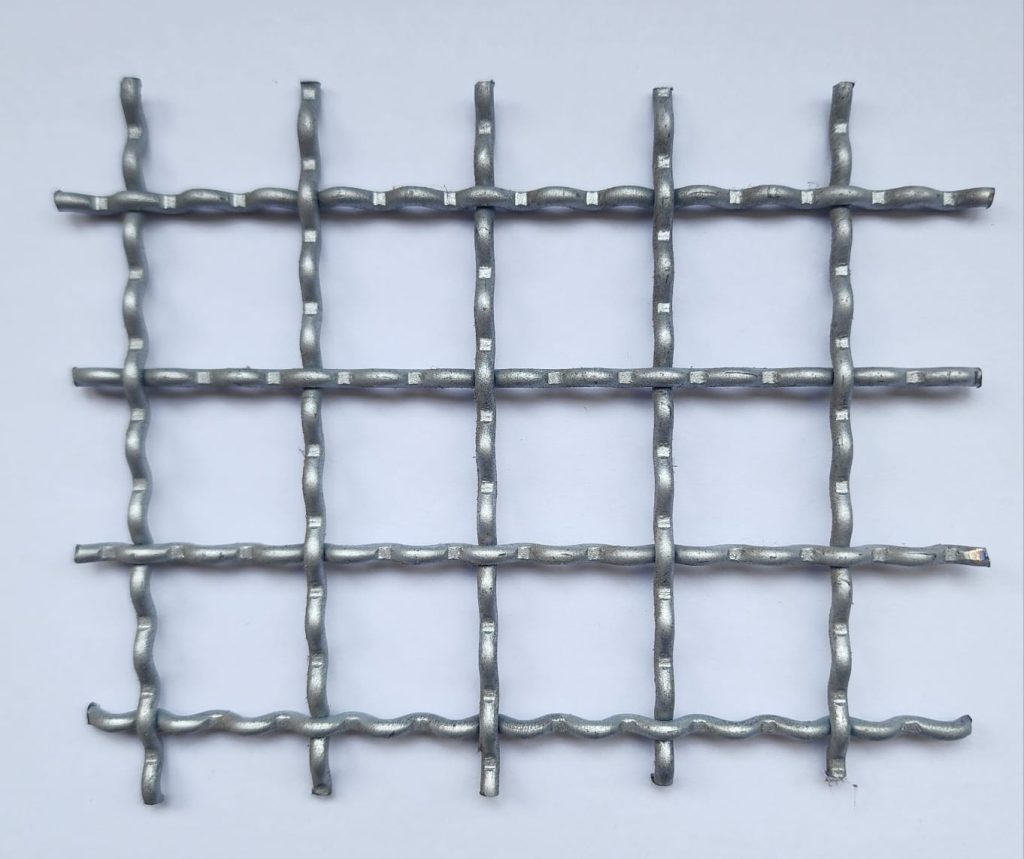

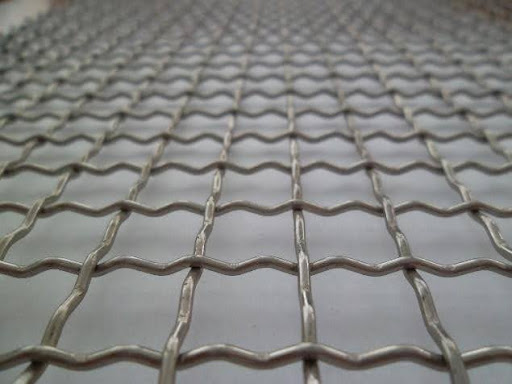

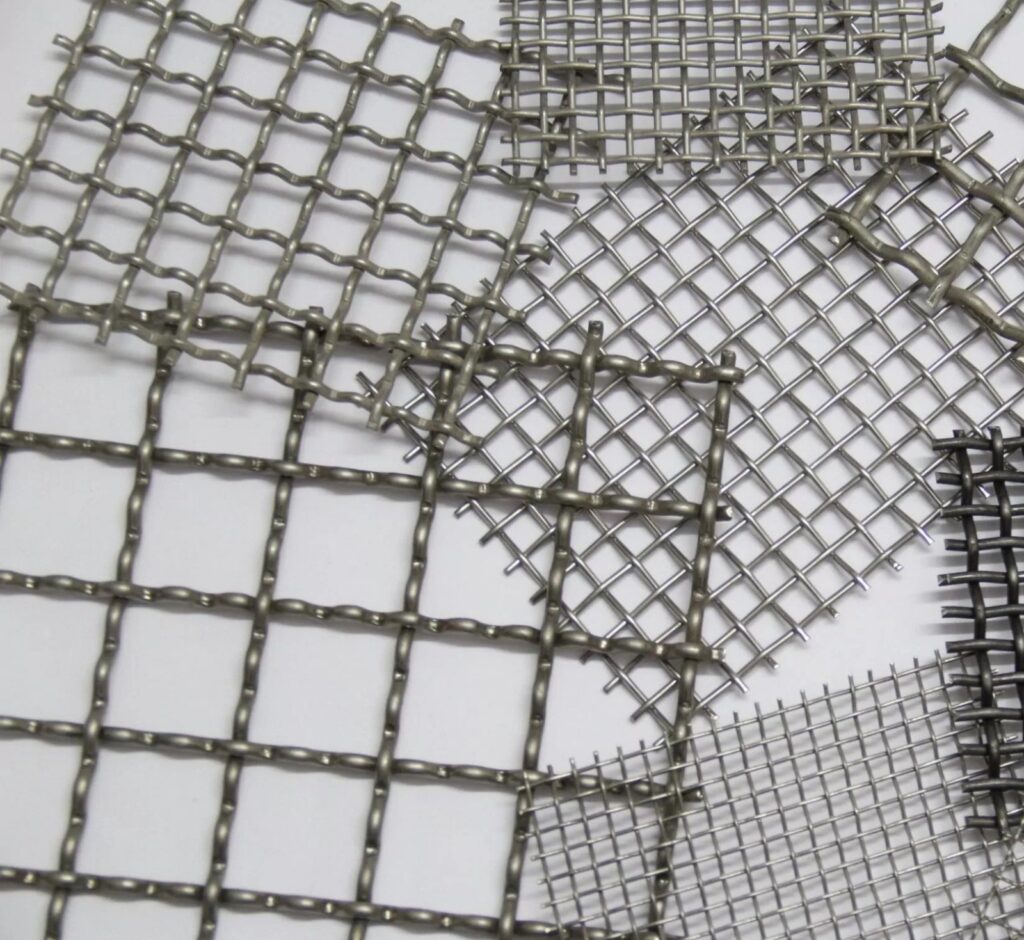

Double Crimp

Both warp and shute wires are crimped at the point of intersection to keep the wires in position. This weave is commonly used for screening operations in smaller openings. Used for medium to heavy wire in relation to screen opening size.

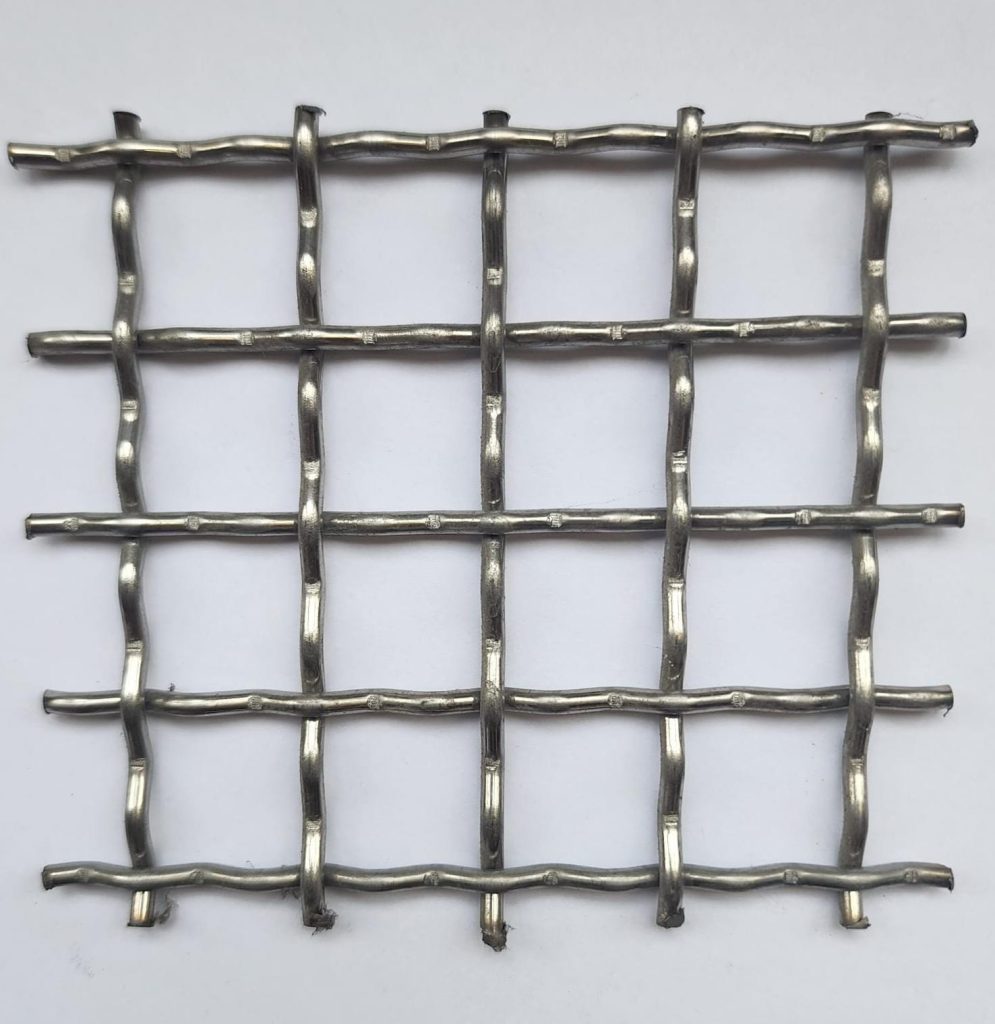

Lock Crimp

The crimping of the warp and shute wires is done in such a manner to actually ‘lock’ the wires together at their point of intersection, offering further assurance of no wire movement.

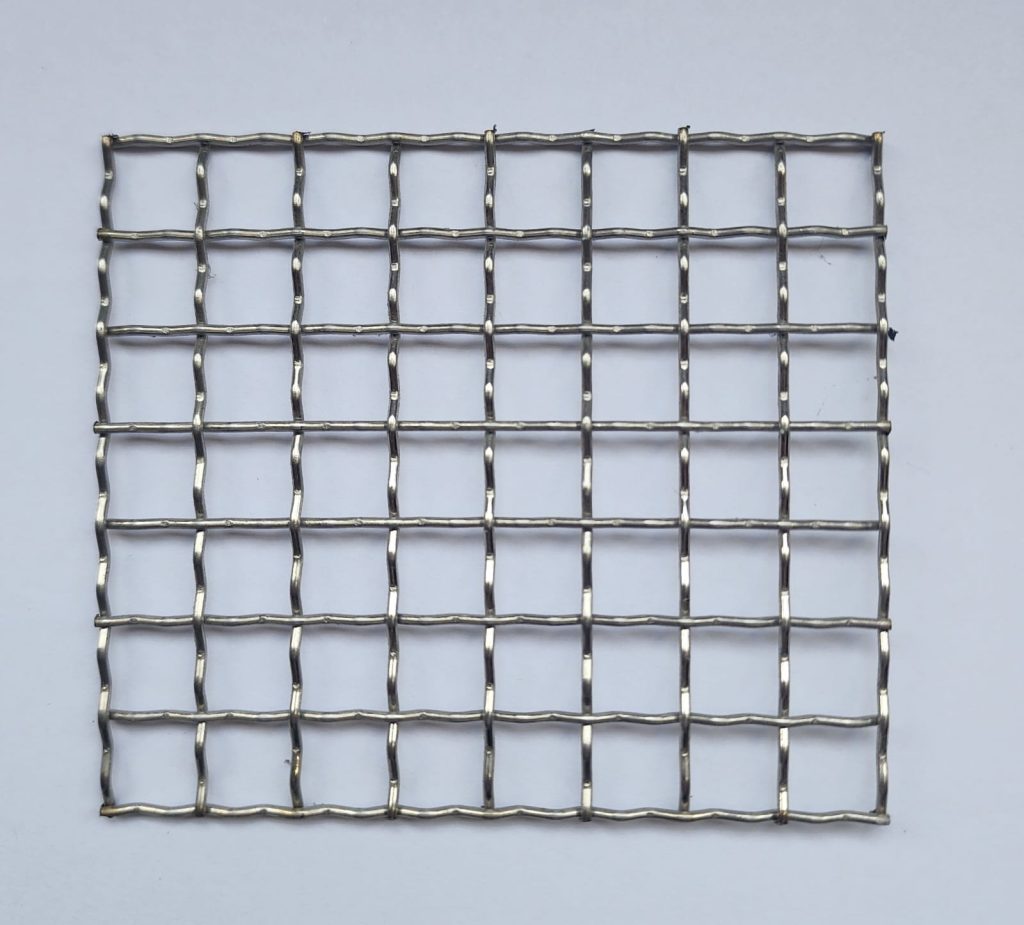

Intermediate Crimp

Both the warp and shute wires are crimped with extra crimps or corrugations between the points of intersection. When open area is important. Extra crimps between the intersections provide a more rigid weave and provide locking and tightness for light wires in relation to the large openings.